A fitting or adapter is used in pipe systems to connect sections of a pipe or a tube, or adapt to different sizes and shapes. Pipe fittings are typically used in general plumbing lines moving gas, steam or liquids. Tube fittings are common in specialty applications where round or square tubes of precision size are required.

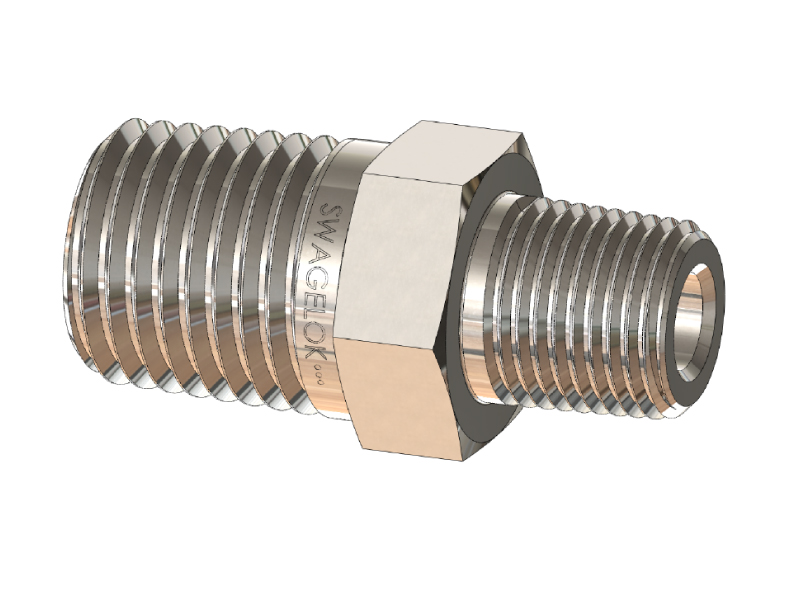

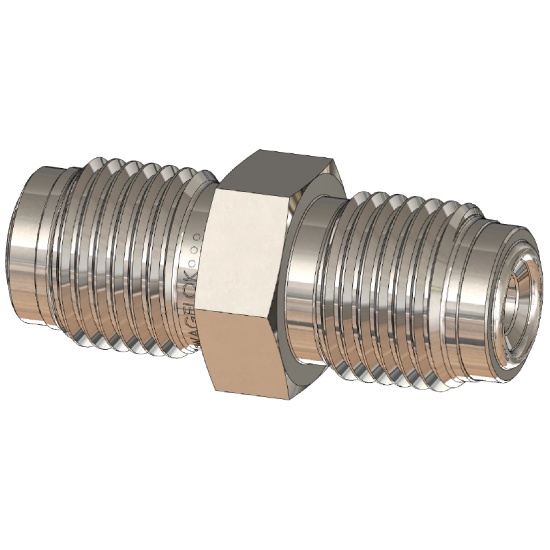

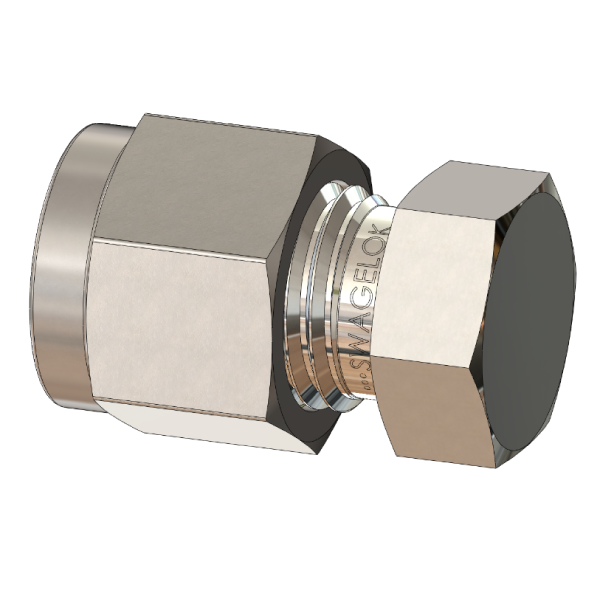

In the context of piping lines a fitting refers to a component joining the ends of pipes or tubes together. The most common example of a fitting is a union where two pipes of the same size and shape are joined. A union is a fitting with ports identical on either end. In the plumbing industry a fitting with identical ends is often called a union in order to quickly signify that the fitting will join pipes of the same size and type. Fittings are designed for pipe and tube leak-tight connections during the lifetime of the piping system.

Fitting Connection Types

Fittings come in a variety of end connections such as:

- NPT male of female thread, NPTF (dry seal)

- BSPT, largely used in European Union, Asia

- ASME or DIN Flange

- KF Flange with quick disconnect clamps in low pressure applications

- CF Flange for ultra high vacuum and all-metal sealing

- Barb Slide-Over Connection

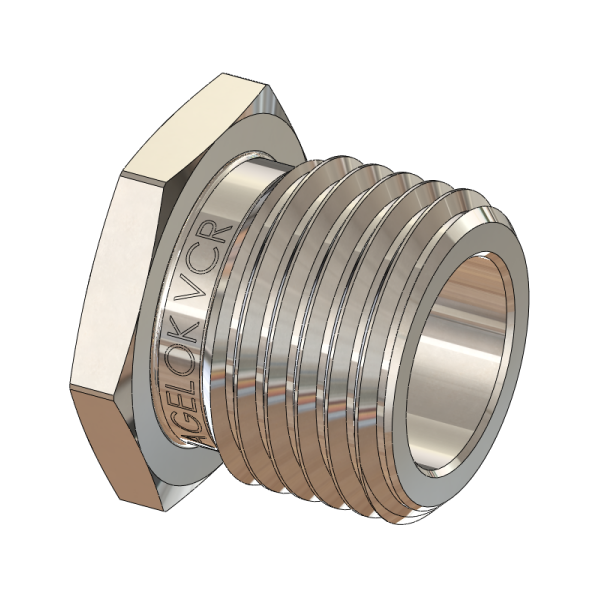

- Compression Tube, Swagelok(™) ferrule type

- Push-In quick connects for water and air hoses

- Socket Weld and Tube Butt-Welds

Fitting Shapes

Similar to a valve, fittings have a variety of shapes, such as:

- In-line

- Tee, which is a fitting with three ends. A tee can be a union or have each end of a different type and size

- 45- 90-degree elbows

- 4- 5-way crosses, sometime 6-way or more for complex pipe routing systems

- Y-shape

Materials used in fittings are typically 304 or 316 stainless steel. Titanium, brass or composites are used for special applications. Important features of fittings are material certification, purity, surface finish and packaging.