Sight glass is a technical term referring to a transparent plug or a fitting separating the ambient environment from the space inside a tank, pipe or process vessel. Simply put sight glasses allow one to see inside a different world where temperature, pressure or chemistry differ from typical conditions. Sight glasses function to transmit a range of light in the visible spectrum, infrared, near-IR or ultraviolet UV. This is important in a variety of industries where process observation and control are required. Sight glasses are constructed from a transparent material, usually borosilicate, quartz or sapphire for visual observation, ZnSe, MgF2, CaF2, Germanium, others, for extended wavelength transmission. See Mode In-Depth About Sight Glasses for a more thorough discussion of sight glasses.

Sight Glass Sealing Methods

Crystalline or amorphous material chosen for the application is sealed into the sight glass housing by a variety of methods depending on factors such as the materials being joined, temperature, pressure, chemical compatibility and other specific requirements. How the window is sealed into a sight glass is critical for the safety and performance of the overall system. See a more detailed discussion of glass sealing methods. Here are quick examples of bonding, brazing, fusing, and gasketing methods:

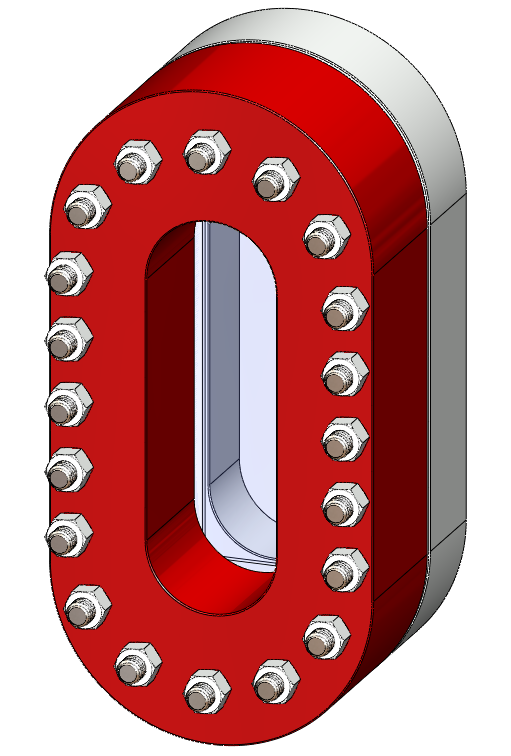

Sight Glass Shapes

Sight glasses are designed to fit into a pipe or a tank using threads or flanges or weld ferrules, all in various sizes and types. For example, National Pipe Taper NPT threads are a common method for affixing a sight glass into a process wall or a pipe. BSPT is used in the European markets, while flanged sight glasses conforming to ASME B16.5 or Metric DIN, ISO geometry are common for larger sized viewing apertures.