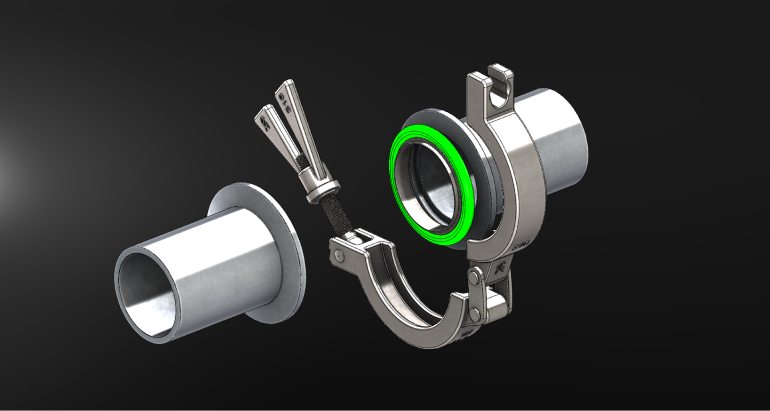

In piping systems quick connect clamps provide mechanical force to the gasket between the two joining ferrules. Sanitary clamps offer smooth surfaces and uniform clamping force distribution.

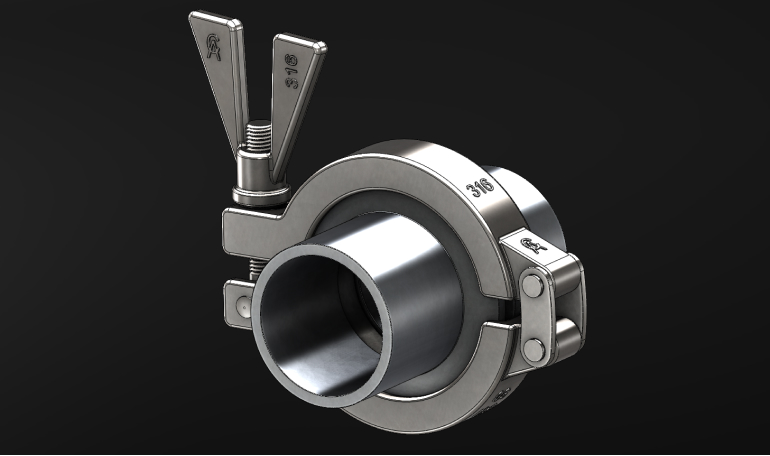

A clamp in piping systems refer to a fitting used to affix two flanges or ferrules together. A clamp typically has a quick disconnect wing-nut on one side of the clamp. Depending on the type of flanges being joined together and also the pressure in the pipe, clamps come in a variety of disconnect methods and geometry accommodating the flange shape. In context of sanitary clamps, these are made from 3-A approved materials such as 304 or 316L stainless steel polished to Ra 30 surface finish, standard, or SF0 to SF6 for biopharmaceutical applications. These requirements are necessary to minimize oxidation, trapping bacteria and particles in equipment for diary, food processing, pharmaceutical and biotech applications.

Sanitary clamps are fast to dismount releasing the pipe joint, important for quick and efficient maintenance. Affixing and disconnecting is achieved by securing fasteners pivoting on a threaded rod integrated into the lower half of the clamp. Typically sanitary clamps fasten with a single bolt on one side and the hinge on the other side. When higher operating pressure is required the clamp is secured with two bolts, one on each side. In either design, single or double-bolt, the pivoting threaded rods remain attached to the clamp. All components of the clamp stay together regardless whether the clamp is secured on the pipe or away while the pipeline is being serviced. This is important in clean rooms where fewer parts result in lower contamination risk and lower operator stress.

The securing nut is often a wing nut or a hex nut for higher pressures. In advanced sanitary clamps such as this SH-I clamp size 2" rated to 870 psi L.J. Star Try-Clamp, the connecting rod has an anti-bump feature where the nut cannot slide away from its secure position when the clamp is fastened. This is achieved with a concave cavity forged into the upper clamp. Releasing the clamp is only possible when the nut is sufficiently loosened to clear away from that cavity in the upper half. An important feature offered on L.J. Star clamps is anti-galling. The nut and the bolt are made from dissimilar materials preventing friction welding and galling.

Typically a sanitary clamp will have a hinge holding the upper clamp half and the lower half together. Double-pin hinge is a more beneficial method to hold the clamp halves together because this provides a more uniform distribution of clamping force as compared to a single-pin hinge design. Flanges in sanitary applications are of the standard geometry, interchangeable between different manufacturers. Typically sanitary clamps are of the ASME BPE, or Bio Processing Equipment geometry, where an elastomer gasket is placed in-between the two mating flanges and compressed when the clamp is secured. This provides a robust leak-free connection under most operating conditions including vibration, high temperature and pressure. Also, sanitary clamps are a common choice in ultra-high vacuum UHV applications.

Sanitary clamps come in a Metric and Standard sizes from 1/2” up to 12”, from 10mm up 300mm tubes and always connect two mating flanges of the same type and size. For joining tubes or pipes of different types an adapter or a reducer is used, with the respective clamp on each end. Sizes and clamp geometry are made to standard ASME BPE 2022 or ISO 2852.