You think and strategize and expect a specific outcome from your big plan. Then you actually go for it and discover the unexpected. A surprise. There is never a dull moment in product development.

Everyone has a plan until you get punched in the face. Over the years we hashed out a smart product line in high pressure sight glasses. The design arrived after many purchase orders manufacturing custom sight glasses for customers around the world. The ultimate in strength and durability, Encole developed sapphire-based sight glasses to support the rigorous needs of the process observation industry. As part of engineering due diligence we tested sight glasses for this new product line.

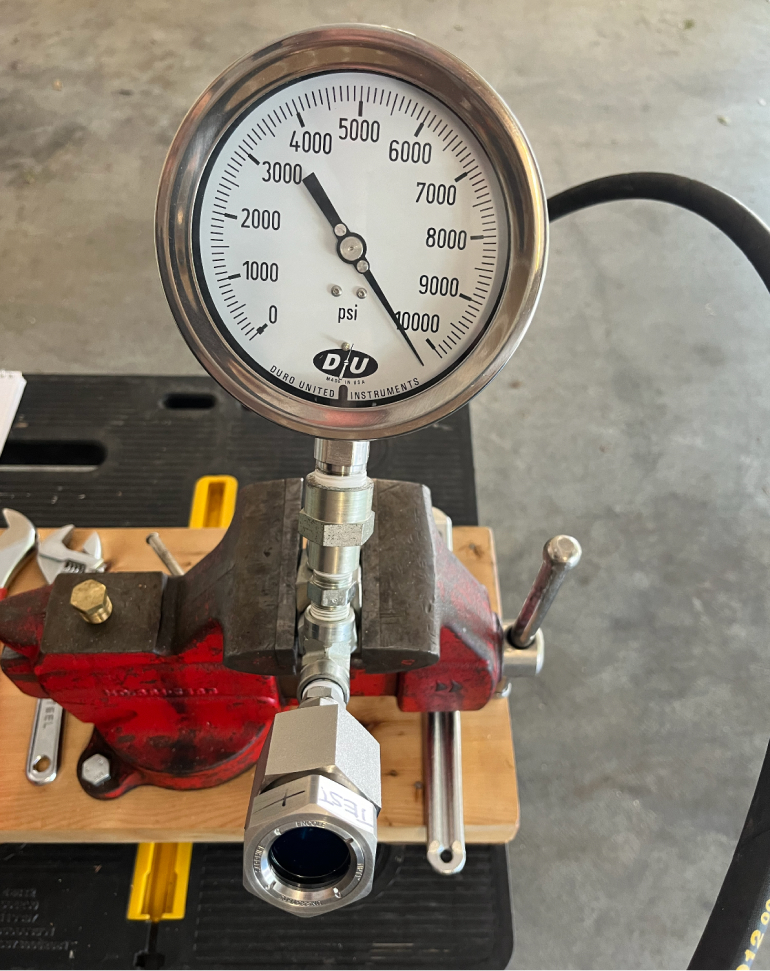

We used ISO-46 hydraulic oil in our pressure tests. This media is chosen for its high flash point (can't ignite easily), its lubrication and anti-rust properties for the test equipment, and most importantly this is a liquid not a gas making it a safe choice in pressure vessels testing. Liquids are incompressible below 300,000 psi (207 Mbar, that's air-free hydraulic oil bulk modulus) and cannot expand as a gas, turning objects into projectiles should the vessel rupture.

The surprise during all this testing came when the camera captured the moment when the test manifold started to unthread itself. We published a video on Instagram and YouTube. This would be a super dangerous situation for a cameraman hand-holding a camera in the line of fire. Calm down everyone. The camera was on a long boom pole. Documenting tests is inherently dangerous. We know this, it's not our first rodeo. This is part of product development where you never exactly know how everything is going to behave until you actually live through it. Our plan worked: expect the unexpected, put the camera away from the operator, observe and adjust in real time. Put safety measures in place. The test was stopped. Everything was re-tightened and the test continued. No one got punched in the face. Besides, the cameraman always survives. Thank you for your comments, much appreciated!

The test protocol was simple: hold the sight glass under design pressure for one hour, and then increase the pressure until the window cracks or ruptures, at ambient temperature. The design pressure is 425 bar. The rupture pressure is calculated at about 1060 bar. These are very high pressures for most commercial applications, so these sight glasses are over-designed. The reason for this over engineering, you understand, is to make them as robust as possible within a target cost. Why design something that is marginal in performance if the extra cost of over designing is small? We went all in on the design keeping the selling price competitive by increasing production quantity. This is based on the simple analysis of product features vs. cost.

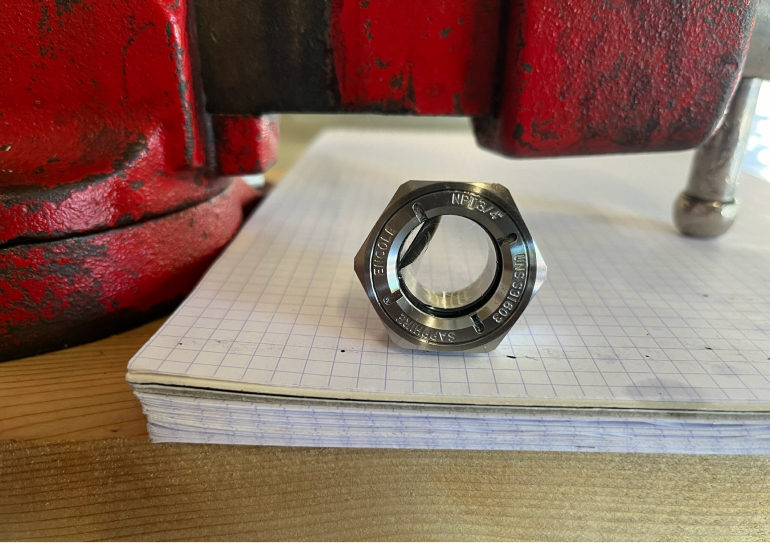

Below are a few photos of the Unit Under Test (Encole sight glass), under pressure. A series of tests were conducted over several days, cycling the pressure at different rates, fast pressure drops, long hold times. The summary of the tests is one word: Passed.

All sight glasses passed the tests at the target pressure. One unit NPT size 3/4" cracked at 10300 psi after 15 minutes under pressure. The window had a hairline crack, the test fluid leaked out a little and the pressure slowly decayed to ambient 1 bar.