AI-Driven, Sight Glass-Enabled Water Usage Optimization

Sight Glass AI-driven real-time maximizing plant water usage efficiency.

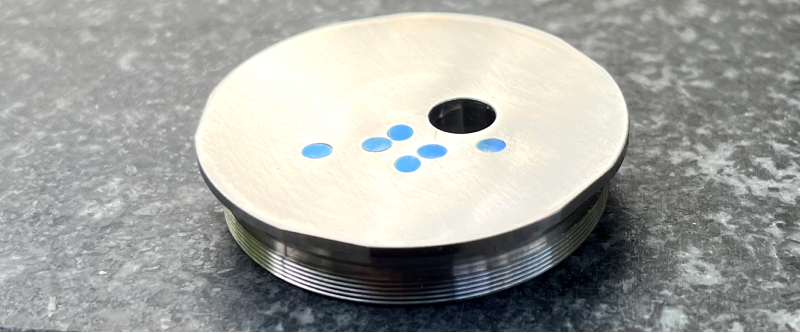

Sapphire windows perfectly in plane with the front of the mounting flange. This sight glass flange was developed to create a uniform boundary layer of water for analysis.

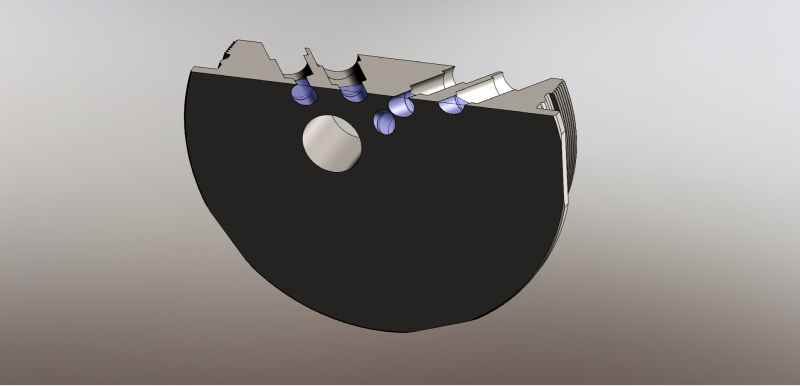

Artificial intelligence, AI sight glass flange with sapphire windows cross-section

The benefit of this design, at a higher level, is to reduce water usage and waste in food production facilities, pulp & paper plants, chemical processing plants. Anywhere in industrial applications using large amount of water, this sight-glass enabling approach will save water. Ultimately water scarcity and quality issues can be addressed in real time.

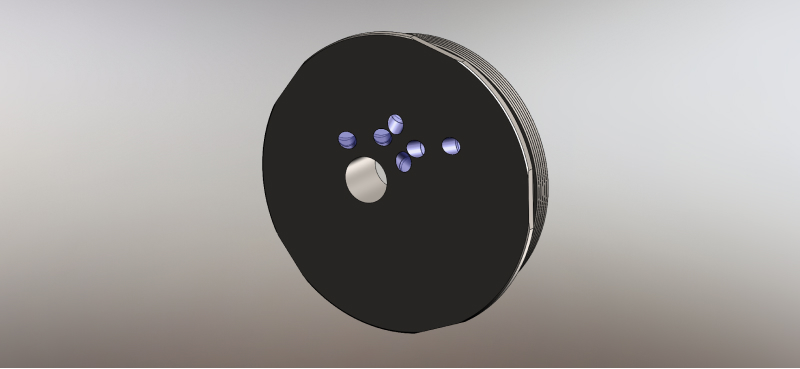

Artificial intelligence, AI sight glass flange with sapphire windows

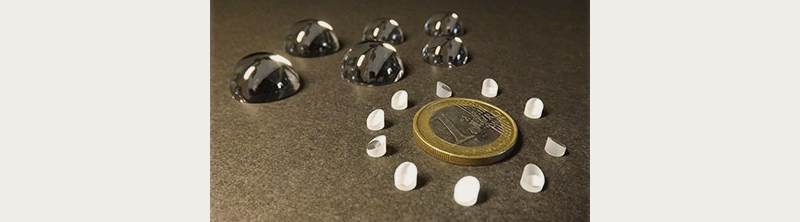

Sapphire lens windows in the flange bores. Notice the tapered top surface in the cylindrical lenses. This surface faces the process side. Both top and bottom surfaces of the lens are anti-reflected coated at broad band wavelength in order to allow maximum information for the AI algorithm. Sapphire lens image credit: Sapphire Micro Optics & Macro Optics from Precision Sapphire Technologies.

Applications and benefits of Sapphire to Metal flush-mounted sight glasses:

- No turbulence at the face of the sight glass

- Uniform boundary layer at the process side

- Window extends into the process side with minimum intrusion into the process

- Consistency from any angle looking through the process media.

Purpose:

- To enable fluid distribution as uniform as possible at the front of the window

- Allow laminar flow within the process vessel, undisturbed by the presence of the sight glass.

This sight glass is designed and manufactured for a customer developing smart water management solutions. Sapphire windows are sealed into the bores by the bonding method: See more about glass sealing methods.