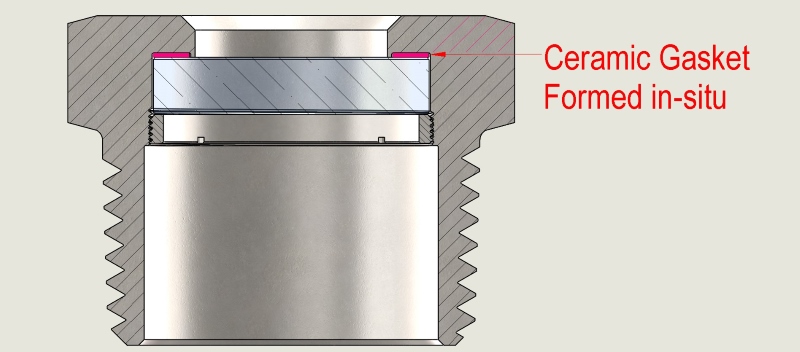

Ceramic Gasket Sapphire Window Sealing, NPT Sight Glass

Maximum temperature 495°C. Also considering brazed windows. PN101470

This is a non-leak-tight sight glass designed for low pressure. Product development for a customer at a University in Castelló de la Plana, Spain

Several types of ceramic sealing materials were tested in three sight glasses assemblies. All components in the three assemblies were the same, the housing, window and the retaining ring. We tried Cotronics 954OD-1 Adhesive. It did not work for us. It needs to be flowable. The idea is to form the gasket in-place, so the material needs to take shape of the space between the adjacent glass and metal. We also tried Omega Engineering OB-700. And we even tried Vitcas HRS sealer.

Sealing ceramic gasket must be:

- Flowable, tooth-paste consistency without fine hard particles

- Highest possible CTE (to compensate for the gap expansion)

- Highest possible operating temperature

- Ideally light color (for laser applications where the light should not be absorbed into the viewport.)

- Does not need to be very strong as an adhesive, we rely on mechanical support inside the assembly.

Regarding ceramic adhesives from any brand: Main issue for sealablity: they are not flowable. The window sits on top of the paste and cannot form into place. Other issues we observed was granular nature of the set paste. It's likely to be porous and not make a contact seal. These products are very good for encapsulating parts. Specifically, when something is fully covered in this paste then the paste will provide the mechanical strength like a cement holding the parts together. For sealing between surfaces, not so much.