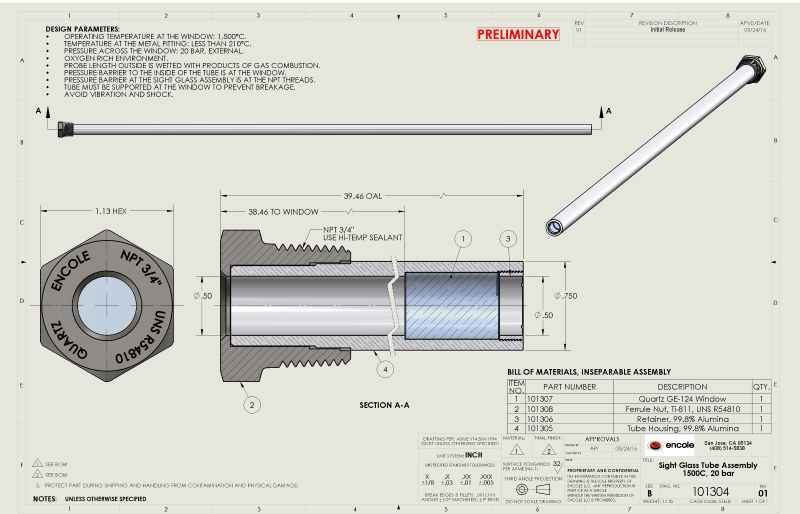

Probe Sight Glass, Alumina 99.8%, Quartz, 1500°C

Optical diagnostics for medical device development. PN101304

The metal nut at the process wall is made from titanium. It can be extended toward the quartz window. However, not all the way to the window. Quartz has a very low coefficient of thermal expansion in comparison to Ti. Because of this mismatch in CTE, Ti is out, we can't use it in this application. Also Ti is out because of 1500°C. Ti reaches its softening point at this temperature. It will lose all of its mechanical strength and will not hold the pressure or vibration.

If we can make Alumina shorter, it will take some vibration. Alumina is a tough material, much better to handle fatigue than Ti. Also alumina's CTE is a better match with quartz, where a ceramic adhesive can be used to seal the two materials. Over the length of the window the adhesive will provide a leak-tight seal for viscous fluids. At 1,500°C air becomes viscous.

Design parameters:

- Temperature at the window: 1,500°C

- Temperature away from the process, at the metal fitting: less than 210°C

- Pressure across the window: 20bar, external. Window is the pressure barrier to the inside of the alumina tube.

- Pressure barrier from process volume to outside the vessel is at the metal fitting.

- Process fluid: combustion gasses.

- Tube must be supported at the window side to prevent breakage.

- Avoid vibration and shock.

Probe sight glass designed for a company developing optical diagnostic and surgical aid medical devices. USA.