Sight Glass Sealing Methods

Methods to hermetically seal glass into a metal housing are brazing, bonding, gasketing and fusing. Each method is explained.

Sealing glass to metal creates a hermetic seal between two dissimilar materials. Choosing the proper sealing method is critical for designing sight glasses and viewports. Some of the main sealing methods are:

- Fusing glass to metal

- Bonding sapphire or quartz to metal with adhesives

- Brazing sapphire or quartz to metal

- O-ring seals or gasketing

- Metal seals, typically C-seals

We will explore in depth each of these methods, when they should be used for the operating conditions.

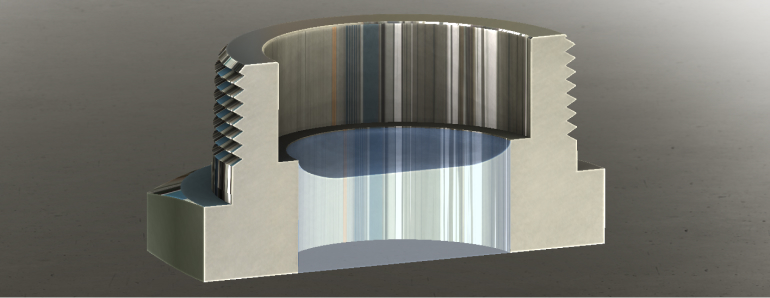

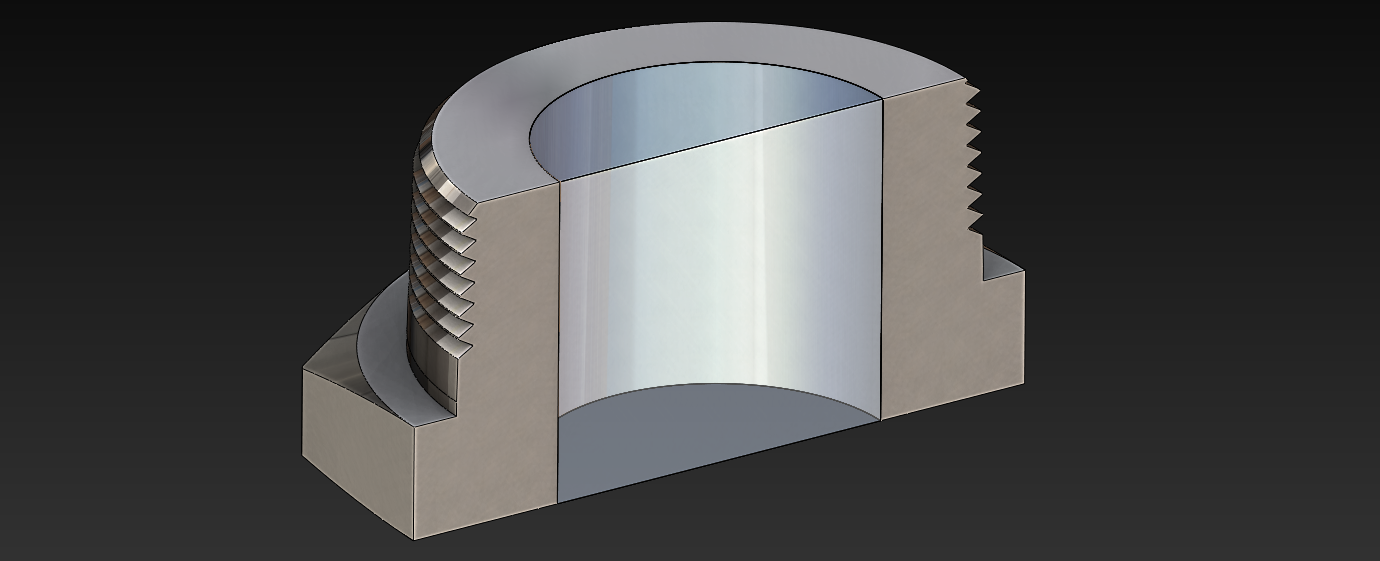

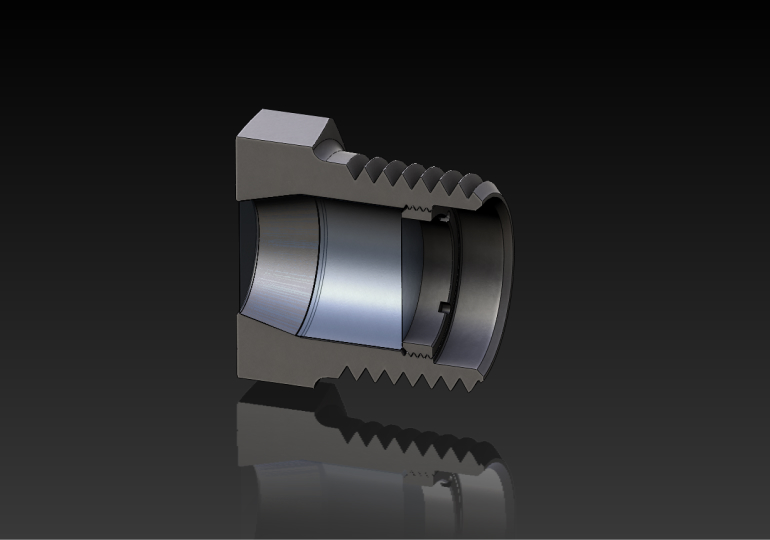

Borosilicate Glass is Fused to a Stainless Steel Housing

The benefit of fused sight glasses are their relatively low cost, very high mechanical strength, and their safety. These types of sight windows are made on a conveyor moving through an oxygen-free tunnel. This is a high volume semi-automated production manufacturing.

During fusing, which takes place inside that tunnel, the glass undergoes several steps. Even before the glass enters the tunnel, the glass is cut to a precise diameter and thickness, placed inside the metal housing on a graphite puck. Both, the glass and the housing sit on the graphite puck. Next, the parts move into the tunnel. The tunnel is purged with Nitrogen gas to make sure there is no Oxygen present. Inside the tunnel the parts are heated by a heating element wrapped around the tunnel. The temperature is above glass melting point. Glass melts onto the graphite puck, and adheres to the metal wall of the housing. At this temperature the metal housing can oxidize, thus the Nitrogen purge. With the glass in liquid state, the metal is at the same temperature expanded radially. This is why it's critical to prepare the glass disk and metal housing internal diameters to have a tight fit before the parts go up in temperature.

In the moment liquid glass touches the metal wall, capillary action takes place at the wall. The glass wicks up the wall creating a lens-effect in the finished product. Next, the parts need to cool down, while continuing to move in the tunnel away from the hot zone. During cooling the glass goes through solidification and annealing phases. At the same time the metal housing cools too, shrinking in diameter.

When the parts cool down to ambient temperature, the housing internal bore is filled with solid glass. And the final diameter is larger than the original diameter the parts started with. In the final product the housing compresses the glass radially, all around with uniform force. The metal now has hoop stress, translating into the glass, making the glass stronger than an unsupported raw glass material without the housing. Example of a commercially available fused sight glass: NPT-Threaded Fused Sight Glass, Borosilicate Window.

When to use fused sight glasses:

- When safety is mostly required. Fused sight glasses do not fly out, should they fail.

- Relatively high operating pressure and temperatures, up to 2000 psi (138 bar), and up to 300°C, respectively.

- Relatively low cost for the given performance.

- Generally available as these are mass-produced in a semi-automated line.

- For sanitary standards - fused sight glasses are smooth, there are no crevices to trap bacteria.

When not to use fused sight glasses:

- When perfect optical clarity is required. Fused sight glasses, if not finished on both sides of the glass will have slight image distortion due to glass wicking at the wall.

Fused sight glasses are naturally strongest of any kind, they are as strong as the housing metal. During an over-pressure failure the glass develops cracks, but still stays in place, does not fly out.

Quartz or Sapphire Bonding to Metal Housing

Bonding glass to metal is a popular method for applications requiring low cost alternatives to brazing. Another advantage of organic sealing is relative elasticity. Organic bonding materials can create a stronger seal than brazing because of forgiving CTE mismatch between crystalline window and the metal housing. There are bonding materials that meet the FDA requirements for food applications, 3-A Standards, or high-strength requirements for high pressure applications in downhole cameras. Example of a commercial bonded sight glass: High Pressure Sight Glass, NPT 1 inch Threaded, 316 Stainless, Quartz Window

When to use bonded sight glasses:

- When high pressure exceeding 2000 psi is required. Bonded sight glasses can be made thicker in order to handle high pressure.

- When perfect optical clarity is required.

- When maximizing the aperture diameter in relation to the overall housing size. Window lands directly onto the sight glass housing without any additional sealing components taking room away from the viewing diameter.

When not to use bonded sight glasses:

- When operating at elevated temperatures. Because there is a mismatch in coefficients of thermal expansion, CTE, between the window and the housing. This creates risk of opening up a gap at the window-to-wall junction. Metal housing at temperature moves away from the quartz or sapphire window.

- When cooling and heating thermal cycling is expected.

Disadvantage of bonded sight glasses is limitation to temperature. Because of CTE mismatch between the quartz or sapphire and the housing metal, these sight glasses can operate near ambient temperature or slightly above. Where bonded sight glasses are preferred is high pressure applications. The layer of the bonding material between the window and the housing is elastic. This allows for even stress distribution over the entire area where the glass lands onto the housing.

Brazing Sapphire or Quartz to a Metal Housing

Brazing sapphire or quartz into metal or other crystalline housings is designed for high temperature applications. Also, brazing quartz and sapphire into housings is used for vacuum application where clean He-leak-tight seals are required. For operating temperatures are up to 1000°C quartz or sapphire can be brazed directly into a housing made of alumina, or yttria stabilized zirconia, (YAG-stabilized zirconia). The most common sight glasses with brazed windows have a metal housing, not a crystalline housing. Typically, quartz or sapphire is metallized with Titanium and then subsequently brazed with a silver-based material into a Kovar sleeve. Then the sleeve with the brazed window is welded into a metal housing, typically Inconel 718, which retains its strength up to 700°C. An intermediate Kovar sleeve is required to accommodate a CTE mismatch between the housing and the crystalline windows materials.

When to use brazing to seal a window into a sight glass:

- Brazing is best used in commercial ultra high vacuum UHV applications.

- When operating at UHV and high temperature at the same time.

- For bake-out temperatures up to 450°C

- When all-metal construction is required. Brazing materials and window metallization materials are typically metals such as Titanium, Gold, Aluminium, Silver, pure elements that do not contaminate the important process.

When not to use brazing method for sight glass sealing:

- In high pressure applications, where the pressure exceeds hundreds of psi, estimate above 50 bar. Quartz or sapphire window is brazed to a thin-walled sleeve on one end. The other end of that sleeve is orbital welded to the main housing. The presence of that thin sleeve limits the pressure. The sleeve can buckle or collapse under great enough pressure. Extra supports maybe designed into the sight glass to prevent buckling, but this complicates the assembly with built-in risks and costs.

- In low fabrication volumes. When cost is an issue at the experimental phase. Developing the proper brazing recipe takes set-up time and engineering. Brazed viewports are best for relatively high volume fabrication runs.

Brazing process of sapphire into Niobium is similar to brazing quartz into Kovar. Because Niobium closely matches CTE of sapphire, the sleeve can be made thicker allowing higher operating pressures of the sight glass assembly.

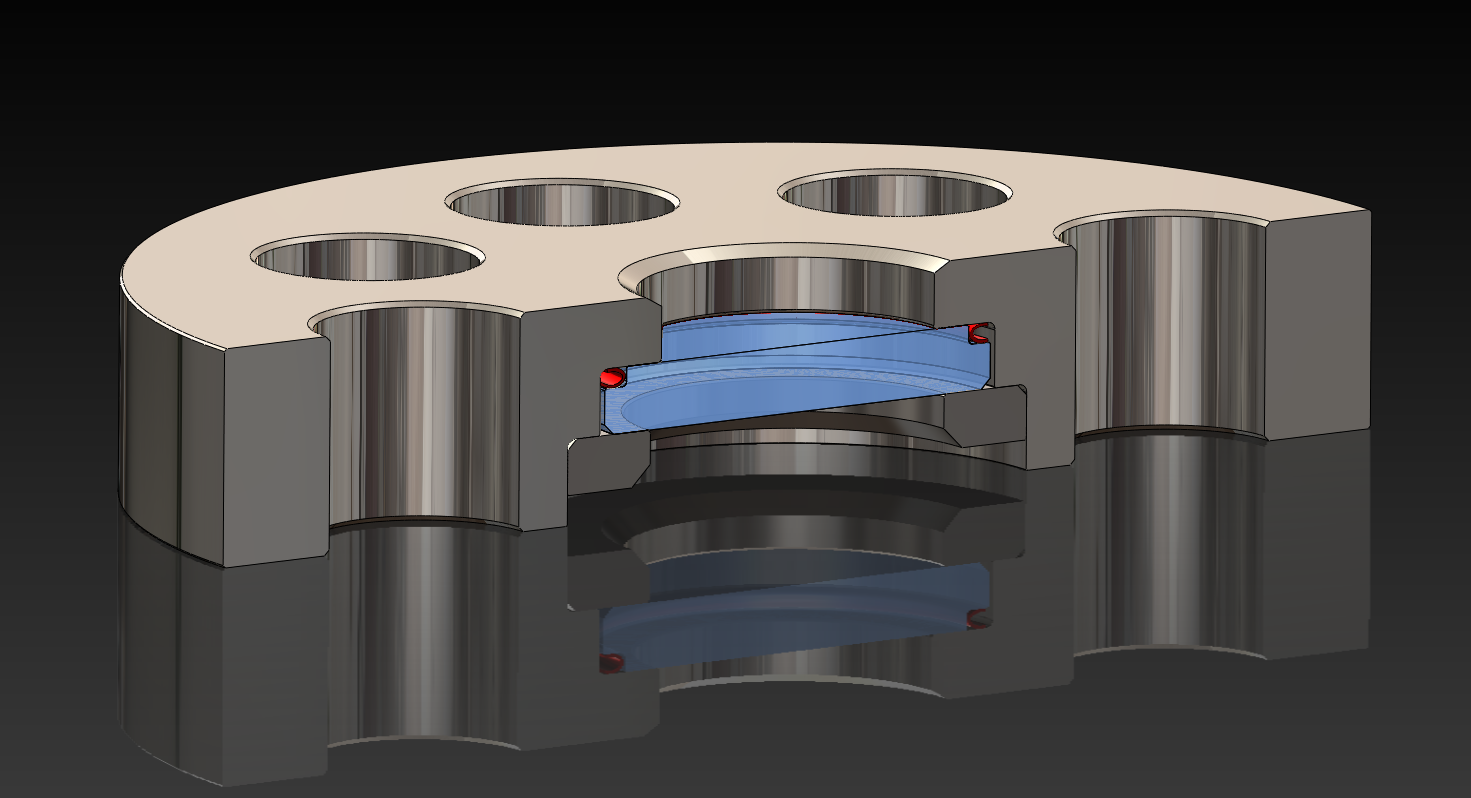

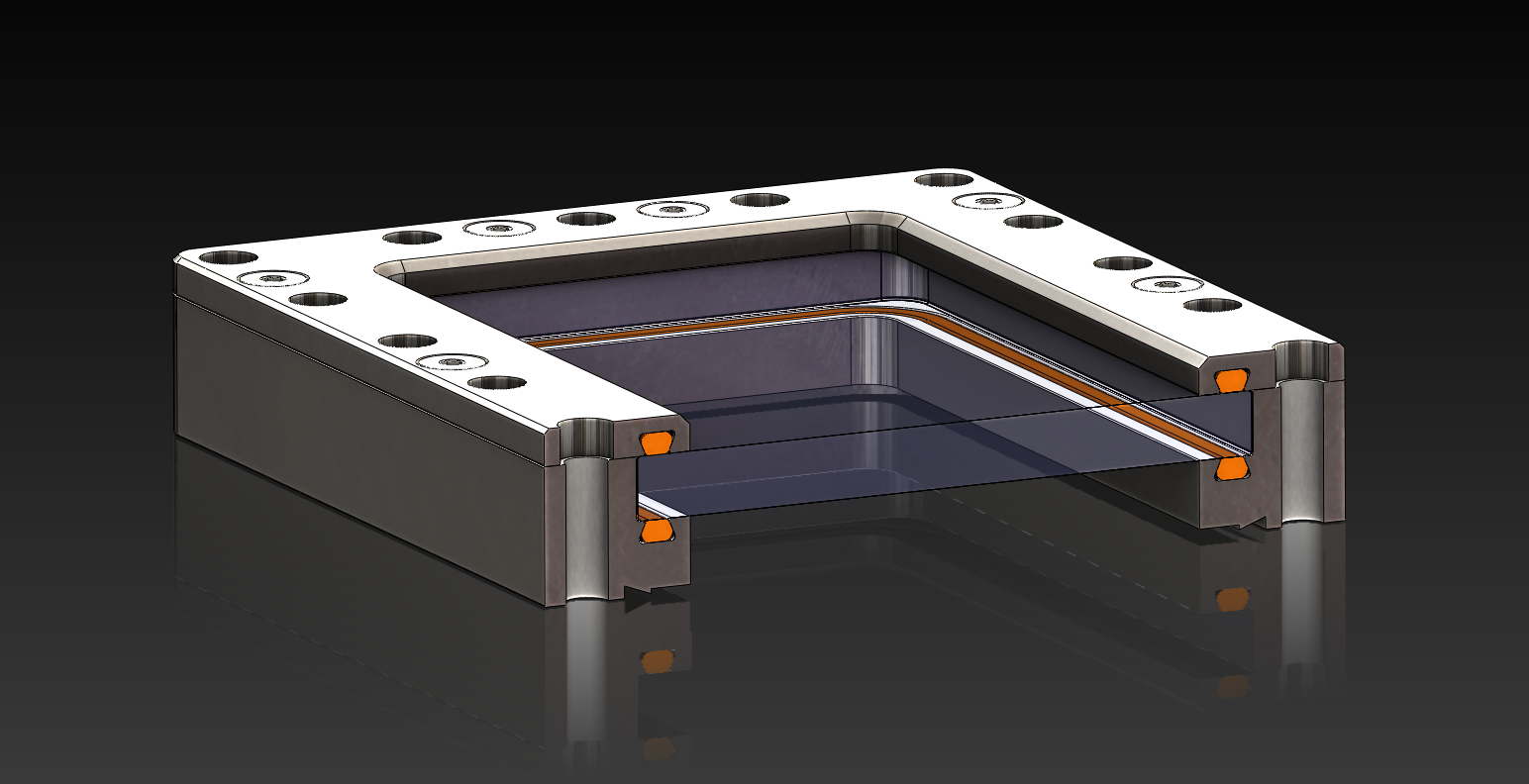

Sealing Glass to Metal With O-Rings

O-rings sealing glass is a simple method widely used in sight glass designs. O-rings sandwich a glass disk and create a seal. For semiconductor or pharmaceutical applications, Viton or Kalrez materials are commonly selected materials for elastomer O-rings for temperatures up to 327°C (Kalrez) and pressures up to 2,000 psi. In plasma chambers elastomer O-rings cannot be used as these materials eventually harden in presence of strong UV light, and therefore lose their sealing ability. An alternative method will work for UV laser chambers using metal seals or shielding techniques.

When to use Elastomer sealing in sight glasses:

- When time to develop a new sight glass is limited. Elastomer O-rings are readily available with proven performance. A custom sight glass can be made within a few days or weeks, unlike with any other method mentioned in this article, generally speaking.

- For pressures less than 6000 psi (410 bar) and temperatures less than 150°C. Higher pressure and temperatures are possible with harder elastomers and PTFE or Silicone S70 - based materials.

When not to use Elastomer sealing in sight glasses:

- When a very long life without maintenance is required. Over ten year in static applications elastomers will perform well. In dynamic conditions with thermal and pressure cycling, lifetime can be limited to less than 5 years, depending on the cycling frequency and amplitude.

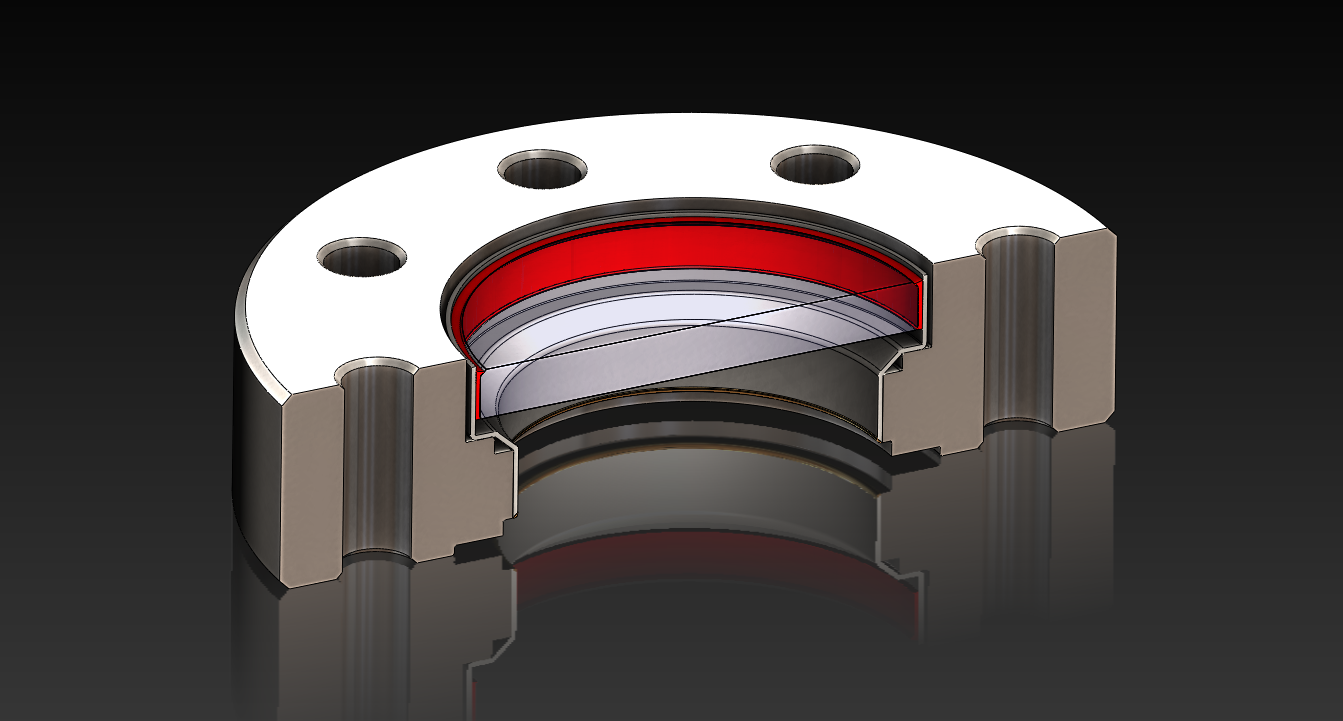

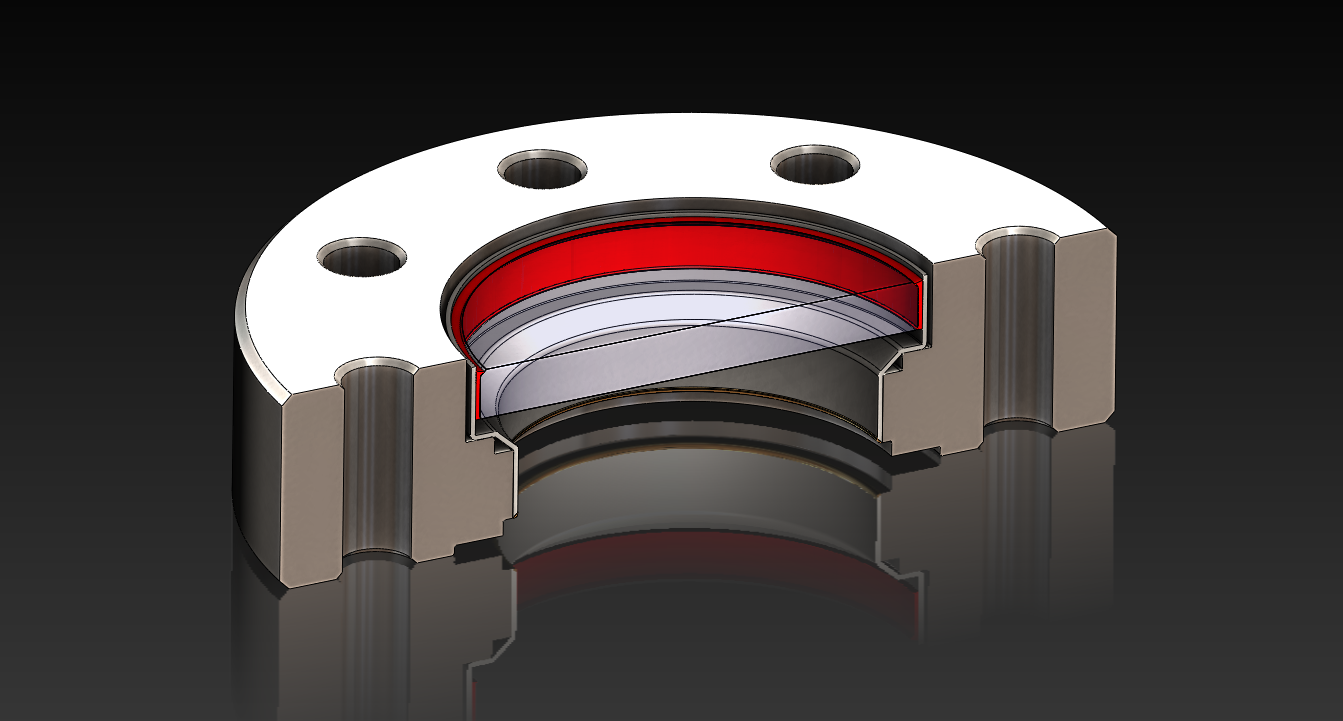

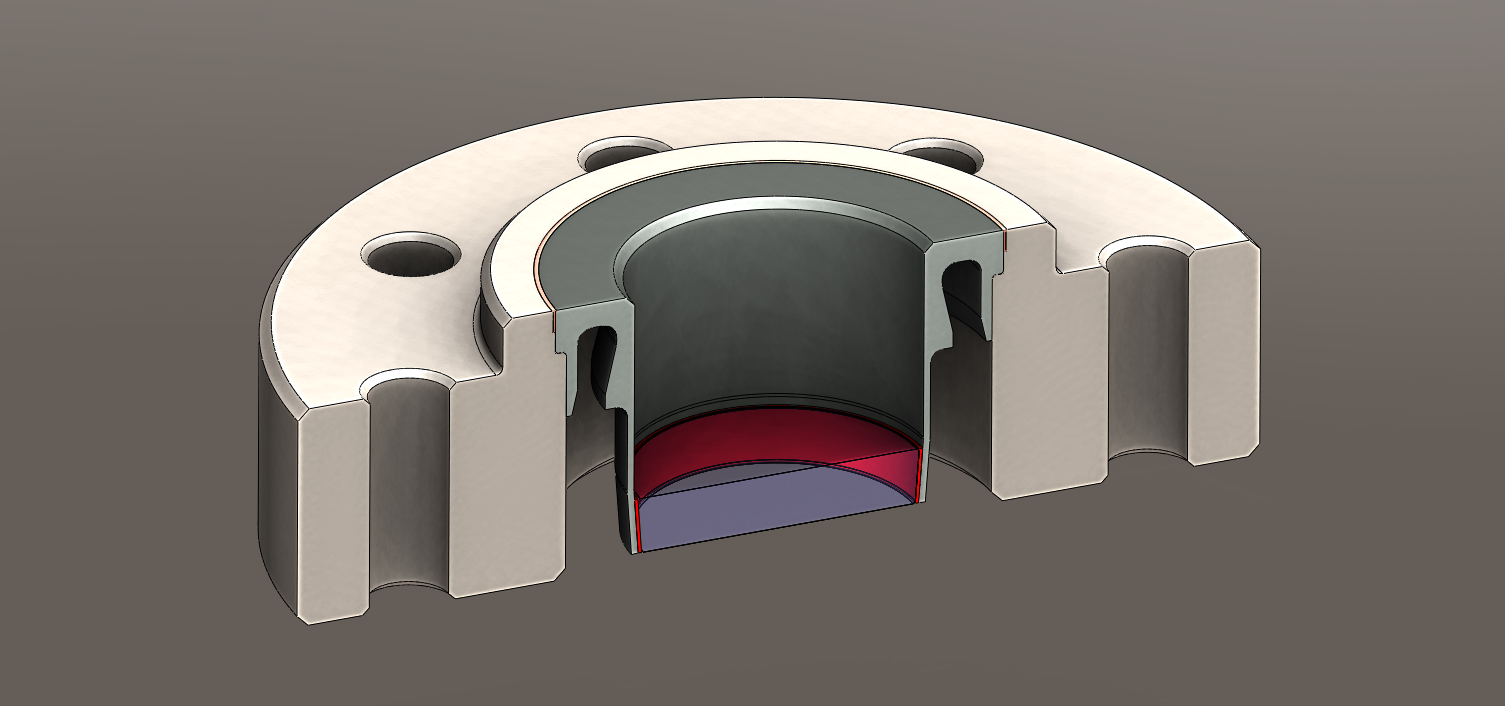

Metal C-Seal Sealing Glass to Metal

Metal C-seals are made in the shape of the letter "C", therefore the name. C-seals come in an external pressure or internal pressure variety, with the C facing toward the pressure. The "C" facing away from the center of the seal is for external pressure; facing into the center of the seal is for internal pressure. For high temperatures C-seals made of Waspaloy is the preferred choice. C-seals are typically plated for a better seal-ability. The thin layer of that plating material crushes between the seal substrate metal and the landing surface where the seal makes contact with the mating part. For example, the seal makes contact with the metal housing on one side and the window on the other side. Plating will fill microscopic imperfections in surface finishes on both sides, creating a Helium gas leak-tight seal. This works for UHV as well as high pressure. Example of a commercial metal-sealed sight glass: NPT-Threaded Sapphire Sight Glass for H2S Service.

When to use metal seals in sight glasses:

- Technically, this is the most capable type of sealing in terms of chemical purity, high operating pressure and temperature, all at the same time.

- When long life over decades is a requirement.

- In the presence of strong UV light, where solarization of materials in the path of light is an issue. Metal seals do not solarize.

When not to use metal seals in sight glasses:

- When birefringence in glass material is an issue. A metal seal exerts a strong force onto the glass. This creates stress which changes material polarization. Birefringence is typically observed in crystalline materials. Most common example is in Calcium Fluoride, CaF2 windows in High UV commercial applications. In optical systems in the visible light spectrum, birefringence in less of an issue.

- Metal seals ere expensive and have long lead time to fabricate. Prohibitive for low cost and quick turn-around applications.

C-seals are a good replacement for elastomer O-rings, where chemical purity is required, pressures are upwards to 100,000 psi (6,890 bar) and temperatures up to 700°C, all at the same time. C-seals have a similar installation procedure as an O-ring. C-seals fit into a groove where hermetic contact is made.